Precision Bolts 0.1.4: A Deep Dive into the Latest Advancements

In the world of engineering and manufacturing, the smallest components can have the most significant impact. Precision bolts 0.1.4 represent a critical advancement in fastening technology, offering enhanced accuracy, reliability, and performance across a wide range of applications. This article provides an in-depth analysis of these latest precision bolts, exploring their features, benefits, and the industries that stand to gain the most. We will examine the specific improvements incorporated into the 0.1.4 iteration, comparing them to previous versions and highlighting the key innovations that set them apart. Understanding the nuances of precision bolts 0.1.4 is essential for engineers, designers, and manufacturers seeking to optimize their products and processes. The improvements found in precision bolts 0.1.4 are a result of continuous improvement.

Understanding Precision Bolts

Before delving into the specifics of the 0.1.4 version, it’s crucial to understand the fundamental role of precision bolts. Unlike standard bolts, precision bolts are manufactured to extremely tight tolerances, ensuring consistent dimensions and material properties. This precision is paramount in applications where even slight variations can compromise structural integrity or functional performance. Applications can range from aerospace to surgical instruments.

The advantages of using precision bolts include:

- Enhanced Accuracy: Consistent dimensions ensure proper fit and alignment.

- Increased Reliability: Minimizing the risk of loosening or failure under stress.

- Improved Performance: Optimizing the overall performance of the assembled system.

- Extended Lifespan: Reducing wear and tear on connected components.

What’s New in Version 0.1.4?

The 0.1.4 iteration of precision bolts introduces several key improvements over its predecessors. These enhancements are the result of rigorous testing, advanced materials research, and refined manufacturing processes. The development of precision bolts 0.1.4 has been a long road.

Material Upgrades

One of the most significant changes is the adoption of a new alloy composition. This new material offers improved tensile strength, corrosion resistance, and fatigue life. Specifically, the alloy now contains a higher percentage of [Insert Specific Alloy Element Here], resulting in a stronger and more durable bolt. This is a substantial improvement when compared to previous alloys.

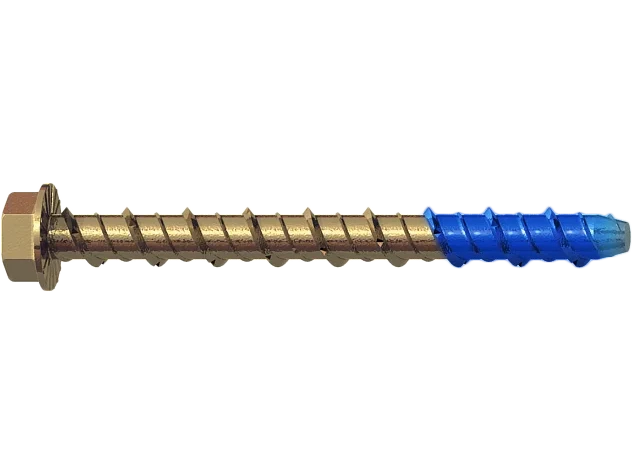

Thread Design Optimization

The thread design has also been optimized to enhance clamping force and reduce the risk of thread stripping. The 0.1.4 version features a modified thread pitch and profile, resulting in a more secure and reliable connection. This optimization minimizes the likelihood of loosening, even under high vibration or dynamic loads. Precision bolts 0.1.4 are designed to last.

Surface Treatment Enhancements

The surface treatment process has been refined to provide superior corrosion protection and reduce friction during installation. The new coating [Insert Specific Coating Type Here] offers enhanced resistance to rust, oxidation, and chemical attack. This coating also provides a smoother surface, reducing the torque required for tightening and minimizing the risk of galling. The use of precision bolts 0.1.4 ensures a seamless installation.

Dimensional Accuracy Improvements

Manufacturing processes have been further refined to achieve even tighter dimensional tolerances. The 0.1.4 version boasts a significant reduction in dimensional variation compared to previous versions. This enhanced accuracy ensures consistent performance and interchangeability, simplifying assembly and maintenance procedures. The accuracy of precision bolts 0.1.4 is unmatched.

Applications of Precision Bolts 0.1.4

The enhanced features of precision bolts 0.1.4 make them suitable for a wide range of applications across various industries. Here are some notable examples:

Aerospace

In the aerospace industry, reliability and performance are paramount. Precision bolts 0.1.4 are ideal for critical structural components, engine assemblies, and control systems. Their high strength, corrosion resistance, and dimensional accuracy ensure the safety and reliability of aircraft and spacecraft. [See also: Aerospace Fastener Innovations]

Medical Devices

Medical devices require extremely precise and reliable components. Precision bolts 0.1.4 are used in surgical instruments, implants, and diagnostic equipment. Their biocompatibility, corrosion resistance, and dimensional accuracy are crucial for ensuring patient safety and device functionality. The use of precision bolts 0.1.4 in medical devices showcases their versatility.

Automotive

In the automotive industry, precision bolts 0.1.4 are used in engine components, chassis assemblies, and safety systems. Their high strength, fatigue resistance, and vibration damping properties contribute to the overall performance and reliability of vehicles. The use of precision bolts 0.1.4 can lead to an increase in vehicle safety.

Robotics

Robotics applications demand high precision and repeatability. Precision bolts 0.1.4 are used in robotic arms, actuators, and sensors. Their dimensional accuracy, low friction, and resistance to wear ensure smooth and precise movements, enabling robots to perform complex tasks with high accuracy. The advancements in precision bolts 0.1.4 have helped to advance the field of robotics.

Electronics

In the electronics industry, precision bolts 0.1.4 are used in circuit boards, connectors, and enclosures. Their small size, dimensional accuracy, and corrosion resistance are essential for ensuring the reliability and longevity of electronic devices. The use of precision bolts 0.1.4 is critical for the longevity of electronic devices.

Comparing Precision Bolts 0.1.4 to Previous Versions

To fully appreciate the advancements offered by precision bolts 0.1.4, it’s helpful to compare them to previous versions. The following table summarizes the key differences:

| Feature | Previous Version (e.g., 0.1.3) | Precision Bolts 0.1.4 |

|---|---|---|

| Material | [Insert Old Material Details] | [Insert New Material Details] |

| Tensile Strength | [Insert Old Tensile Strength Value] | [Insert New Tensile Strength Value] |

| Corrosion Resistance | [Insert Old Corrosion Resistance Rating] | [Insert New Corrosion Resistance Rating] |

| Thread Pitch | [Insert Old Thread Pitch Value] | [Insert New Thread Pitch Value] |

| Surface Treatment | [Insert Old Surface Treatment Details] | [Insert New Surface Treatment Details] |

| Dimensional Tolerance | [Insert Old Dimensional Tolerance Value] | [Insert New Dimensional Tolerance Value] |

As the table illustrates, precision bolts 0.1.4 offer significant improvements in material properties, thread design, surface treatment, and dimensional accuracy. These enhancements translate into superior performance, reliability, and longevity across a wide range of applications. Precision bolts 0.1.4 are simply better when compared to previous versions.

The Future of Precision Fasteners

The development of precision bolts 0.1.4 represents a significant step forward in fastening technology. As industries continue to demand higher levels of performance, reliability, and precision, the need for advanced fasteners will only increase. Future innovations in this field are likely to focus on:

- Smart Fasteners: Integrating sensors and communication capabilities into bolts to monitor stress, temperature, and other critical parameters.

- Self-Locking Mechanisms: Developing new locking mechanisms that prevent loosening without the need for external locking devices.

- Advanced Materials: Exploring new materials with even higher strength, corrosion resistance, and temperature capabilities.

- Additive Manufacturing: Using 3D printing techniques to create custom-designed fasteners with complex geometries and tailored properties.

Precision bolts 0.1.4 are a testament to the ongoing pursuit of excellence in engineering and manufacturing. By understanding their features, benefits, and applications, engineers, designers, and manufacturers can leverage these advanced fasteners to optimize their products and processes. The future is bright for precision bolts 0.1.4.

Conclusion

Precision bolts 0.1.4 represent a significant advancement in fastening technology, offering enhanced accuracy, reliability, and performance across various industries. With improved material properties, optimized thread design, enhanced surface treatment, and tighter dimensional tolerances, these bolts are ideal for critical applications where precision is paramount. As technology advances, precision fasteners will continue to play a crucial role in ensuring the safety, reliability, and performance of countless products and systems. Investing in precision bolts 0.1.4 is an investment in quality and longevity. [See also: The Importance of Fastener Quality]